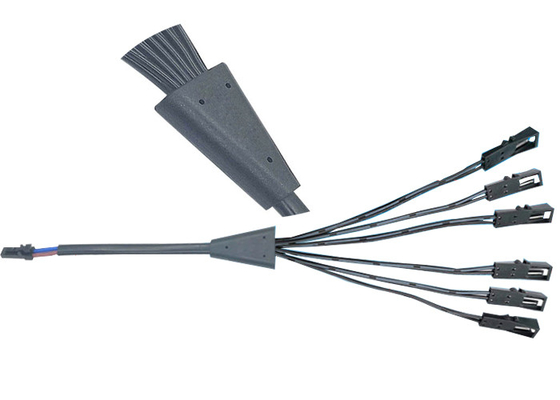

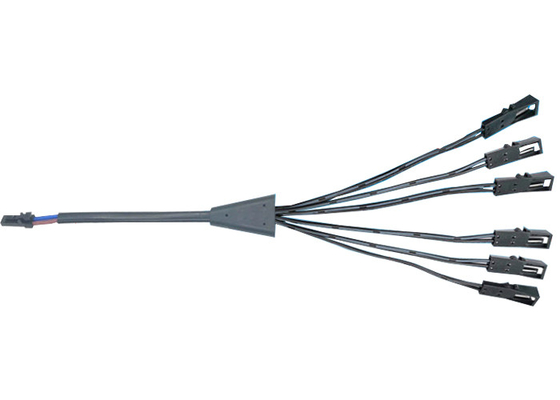

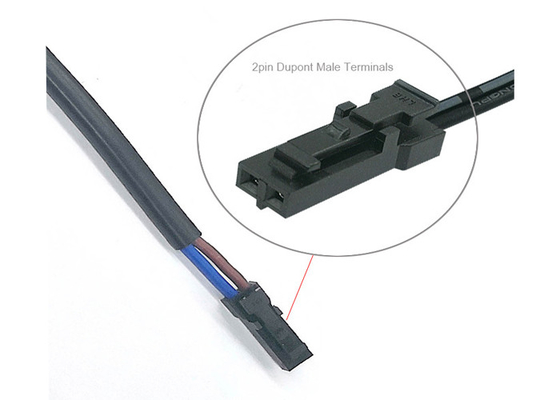

2pins Communication Wires And Cables Dupont Male 18AWG Six-port Junction Box Splitter Wires

Product information:

A cable that transmits information signals between geographically separated points. The heart of a communications cable is the transmission medium, which may be optical fibers, coaxial conductors, or twisted wire pairs. A mechanical structure protects the heart of the cable against handling forces and the external environment. The structure of a cable depends on the application

Optical communications cables are used in both terrestrial and undersea systems. Optical communications cables for terrestrial use may be installed aerially, by direct burial, or in protective ducts. The terrestrial cable requires only enough longitudinal strength to support its own weight over relatively short pole-to-pole spans, or to allow installers to pull the cable into ducts or lay it in a trench. For the undersea cable, the high-strength steel strand allows it to be laid and recovered in ocean depths up to 4.5 mi (7315 m).

Parameters:

| Wire gauge |

18AWG |

| Wire length |

250mm or customized |

| Wire color |

Black or customized |

| Pin |

2pins or customized |

| Core material |

Cooper |

| Insulation material |

PVC |

| MOQ |

Small quantity can be accepted |

| Lead time |

3-15 days |

| Certificate |

RoHS,CE,UL,TUV,ISO |

| Test |

Professional breakover and pulling force test before goods sent out |

| Wire gauge |

20AWG |

|

Color

|

Customized |

| Customized |

Yes |

| Feature |

Waterproof /Flame retardant |

Production Capacity:

We Make Around Five Million Crimps Per Month and We Have Ambitious Expansion Plans to Make Around Ten Million Crimps Per Month .

Competitivenes…

We Maintain Competitiveness with the Following Steps

- Procurement of Raw Materials from the Most Cost Effective Sources,

- Keeping the Least Inventory.

- Adoption of the Best Process to Increase Productivity to the Optimum Level.

- Adoption of the Latest Techniques,

- Value Engineering as a Continuous Process

- Best Quality Product with Competitive Price.

- 100% Acceptance with Customers (Zero Defects)

Shipping:

1. FedEx/DHL/TNT/UPS/EMS/Aramex/SF for samples, Door-to-Door;

2. By Air or by Sea for batch goods;Airportport receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3-7 days for samples; 10-30 days for batch goods.

FAQ

Q: When will you start to help design?

A: We sketch simple solution for initial discussion, after quotation and order placed then start to drawing and double confirm with client for the design.

Q:How can i get the price?

A:We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q:Can I buy samples placing orders?

A:Yes.Please feel free to contact us.

Q:Where can I find custom wire harness manufacturers near me?

A:We strive to make sourcing cable assemblies and wiring harnesses easy. We own 3 facilities in china , so we stay intimately abreast of the day-to-day operations of each. We are UL®-approved for wire harness manufacturing so you can be confident in the exact requirements of your project being met by our design staff. we ensure your project is completed on-time and on-budget, using the best materials and methods available in wire harness manufacturing today. So no matter where your project takes place, be confident knowing SYH can supply all the components needed to produce a top-of-the-line custom cable harness.

Q:What is the wire harness manufacturing process?

A:For any custom cable or wire harness project, our engineers and design staff first listen to our clients. By intimately understanding the “what, when, where, and how” behind the harnesses’ intended application, we can begin the manufacturing process. Often, we need to understand the electrical needs, as well as, the space constraints first and foremost and build our systems within the project’s scope concerning these dimensions. Each process is a little different for each custom harness and we have more than 5,000 tools at their disposal to get the job done. Depending on the level of precision the project calls for, we can either deploy hand tools, semi-automated machines, or fully automated machines. Even though we depend on automation to provide exact design specifications, a lot of work is still done by hand by our skilled manufacturers due to the multitude of complex steps involved. Our process engineers deploy time and money savings techniques like kanban manufacturing and just-in-time ordering to provide the very best products possible, on-time, and within our client’s budget.

Q:What is the UL® standard for wire harness manufacturers?

A:United Laboratories (UL) is one of only a select few corporations that have been approved by the U.S. Occupational Safety and Health Administration (OSHA) for testing and certifying both safety and uniform functionality of wiring and cable components. By only using UL-certified components, we can ensure our products operate the same way, within known specification ranges, year in and year out. Rather than having to design a cable from scratch each time, this allows design staff to focus on other project variables such as weight strain reduction within the harness, type and size of conductors, insulation material, etc. If you don’t see that your wire harness and cable assembly manufacturers are using UL-certified wires and cables, don’t trust your integral electrical systems to a system which could fail when you need it the most.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!