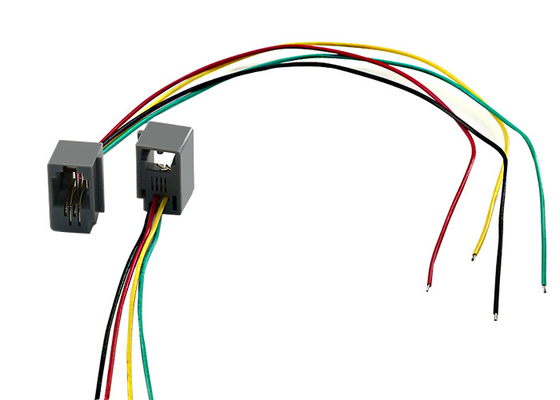

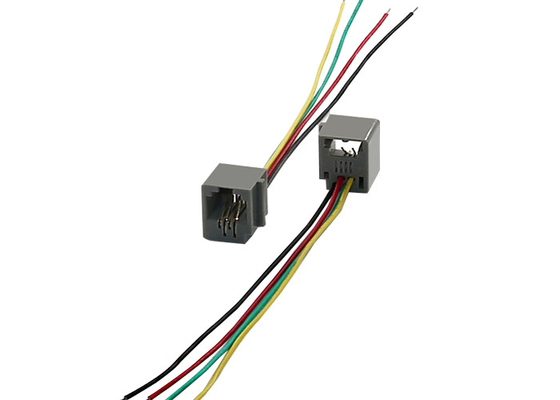

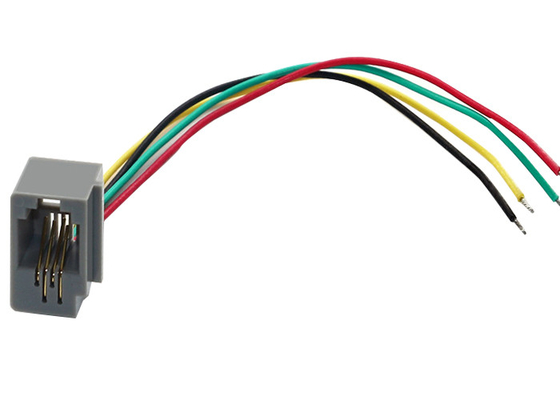

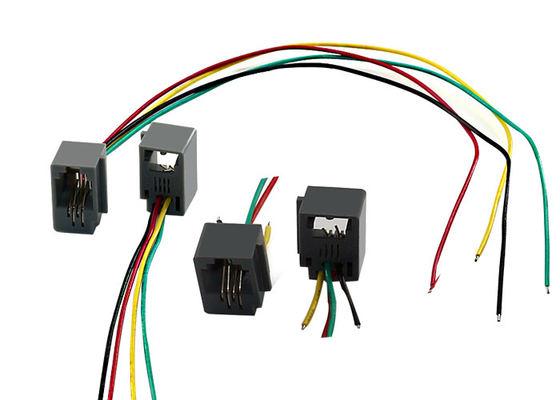

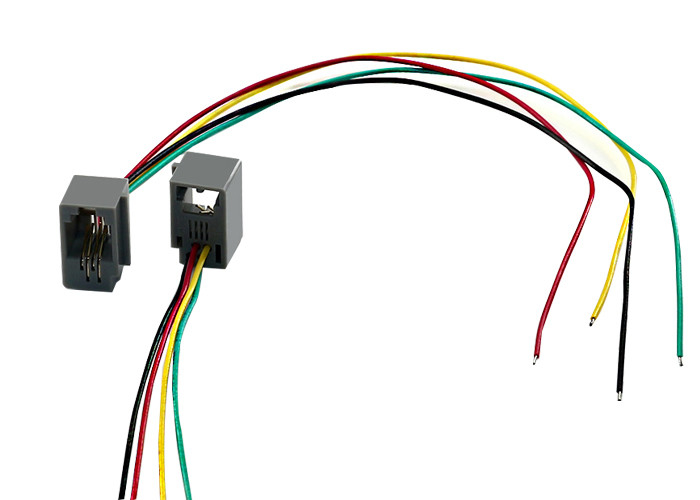

220V Communication Wires And Cables 8pins 18AWG 200mm Telephone Receiver Cable

Product information:

The quality of the wire harness material directly affects the quality of the wire harness. The choice of wire harness material is related to the quality and service life of the wire harness. In the selection of wire harness products, don't be greedy for cheap, cheap wire harness products may use poor quality wire harness materials.

Parameters:

| Wire gauge |

18AWG |

| Voltage |

220V |

| Current |

1A |

| Pitch |

2mm |

| Wire length |

200mm or customized |

| Wire color |

Customized |

| Pin |

4 pins or customized |

| Core material |

Cooper |

| Insulation material |

PVC |

| MOQ |

Small quantity can be accepted |

| Lead time |

3-15 days |

| Certificate |

RoHS,CE,UL,TUV,ISO |

| Test |

Professional breakover and pulling force test before goods sent out |

| Wire gauge |

20AWG |

|

Color

|

Customized |

| Customized |

Yes |

| Feature |

Waterproof /Flame retardant |

How to distinguish the quality of the harness? Understand the material of the wiring harness. The following is the material of wire harness selection.

The wiring harness is generally composed of wires, insulating sheaths, terminal blocks and packing materials.

1. Material selection of terminal

The copper used for terminal materials (copper parts) is mainly brass and bronze (brass is slightly lower in hardness than bronze), of which brass accounts for a larger proportion. In addition, different coatings can be selected according to different needs.

Second, the choice of insulating sheath

The commonly used materials of sheath material (plastic parts) are PA6, PA66, ABS, PBT, pp, etc. According to the actual situation, flame retardant or reinforcing materials can be added to the plastic to achieve the purpose of reinforcing or flame retardant, such as adding glass fiber reinforcement.

Third, the choice of wire harness

According to the different use environment, choose the corresponding wire material.

Fourth, the choice of dressing materials

Wire harness bandaging plays the role of wear resistance, flame retardant, anticorrosion, interference prevention, noise reduction, and beautification of appearance. Generally, the bandage material is selected according to the working environment and the size of the space. There are usually adhesive tapes, corrugated pipes, PVC pipes, etc. in the choice of packing materials.

FAQ:

Q: When will you start to help design?

A: We sketch simple solution for initial discussion, after quotation and order placed then start to drawing and double confirm with client for the design.

Q:How can i get the price?

A:We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q:Can I buy samples placing orders?

A:Yes.Please feel free to contact us.

Q:What is wire harness manufacturing?

A:Wire harness manufacturing entails creating a custom set-up of electrical wires and/or cables based on the task needed by our client. You can imagine this can run a pretty large gambit of different applications. As custom wire harness manufacturers, it is our job to fully understand the client’s needs, examine where the cable harness will be used, and consider a host other factors that determine the material types and attributes needed for the wiring harness to perform under even the harshest of conditions for years of faithful, continued service. At SYH, we have the tools and experience to create just about any wiring harness application a client can think of. We usually produce a small number of prototypes to ensure our engineers have everything perfect for the unique application our client is intending before we move on to larger-scale production.

Q:What are wiring harnesses used for?

A:Wiring harnesses are used in everything from remote control cars to jumbo jets. For example, the desktop computer you may be using currently has a myriad of different harnesses for data and power transfer, all to let you view a page like this one. Inside your vehicle are reams of cables, wires, terminals, and connectors that have to run through the entire vehicle in order to connect all the different components that allow you to simply drive from A to B. The harness itself sounds simple, but it can be rather complex when different connections, terminations, conductor sizes, sheathing, strain reliefs, and many other considerations have to come into play depending on the needs of the project. Our engineers design a complete system around the wires and cables needed to power electrical systems, transfer high speed data, and send and receive signals. If you’re ready to discuss your project’s unique requirements, talk over your options with a knowledgeable representative now.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!