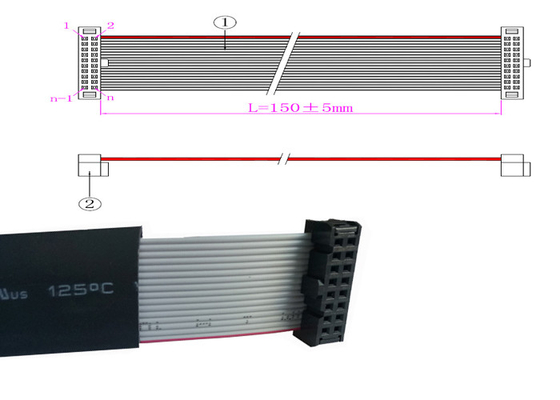

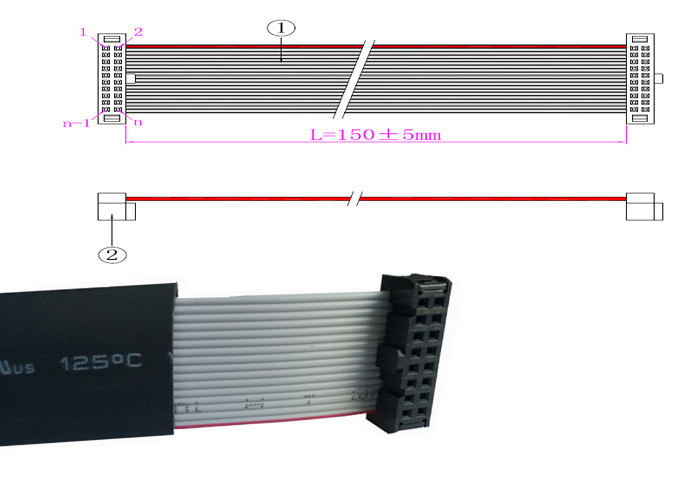

1.27P IDC Ribbon Cable Waterproof 10pins Low Frequency Two Piece-Flexible Flat Cables

Product description :

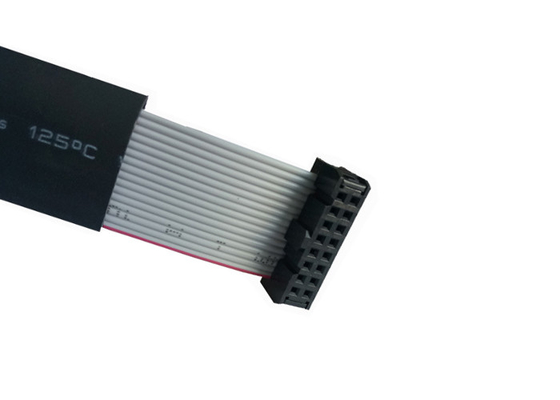

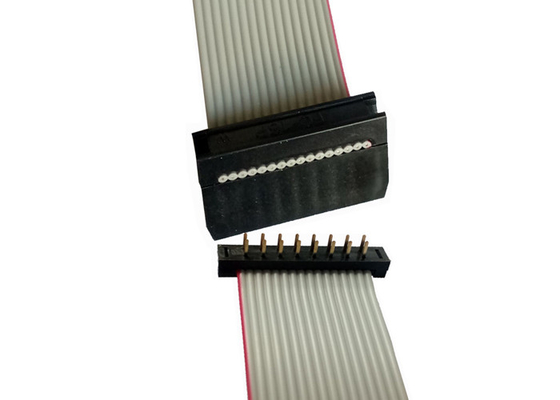

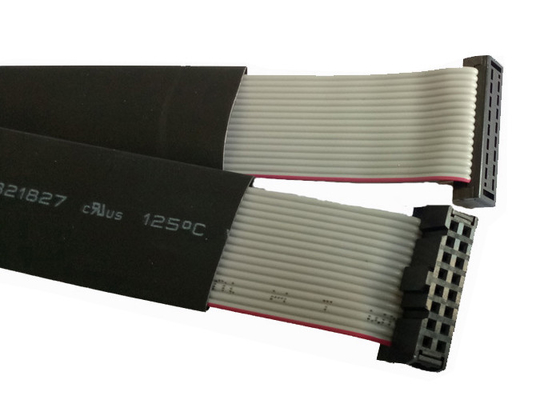

A ribbon cable is a flat, thin cable composed of multiple small-grade cables placed parallel to each other. With each core situated side by side, they form a wide-flat cable resembling a piece of ribbon, hence its name. This type of cable is mostly used in electronic systems that require multiple data buses to link internal peripherals, such as disk drives to their respective drive controllers.

Features:

1. Small size and light weight is the only solution to meet the requirements of miniaturization and movement;

2. It can be moved, bent and twisted without damaging the wire, and can meet different shapes and special package sizes;

3. The IDC Ribbon cables has excellent electrical properties, dielectric properties and heat resistance;

4. The IDC Ribbon cables has higher assembly reliability and quality.

Parameter:

| Product name |

Two Piece-Flexible Flat Cables |

| Sheath material |

PA6T+30%Glass Fiber,UL94V-0 |

| Contact material |

Phosphor Bronze |

| Current Rating |

0.5A |

| Insulation Voltage |

200V AC/DC |

| Insulation Resistance |

1000MΩ Min |

| Operation Temperature |

-40℃ to +105℃ |

| Processing Temperature |

260℃ for 10 second |

| Interface type |

AC/DC |

| Features |

Fire resistance / flame retardant |

| Connectors |

1.27-10P |

| Work frequent |

Low frequency |

| Shape |

Strip |

| Tensile Strength |

100 |

| PIN |

10pins |

| Pitch |

1.27mm |

| Wire gauge |

30AWG or customized |

| Wire length |

150mm or Customized |

| Wire Color |

Red edge gray row or Customized |

| Certificates |

RoHS,CE,UL,TUV,ISO |

| MOQ |

Small quantity can be accepted |

| Sample |

Samples confirmed first before mass production |

| Sevice |

OEM ODM accepted |

| Delivery Time |

3-15 days upon receipt of payment |

| Packaging |

00/200/300/500pcs per bag , then outside carton |

| Test |

Professional breakover and pulling force test before goods sent out |

| Lead time |

3-15 days |

The quality of the wire harness material directly affects the quality of the wire harness. The choice of wire harness material is related to the quality and service life of the wire harness. In the selection of wire harness products, don't be greedy for cheap, cheap wire harness products may use poor quality wire harness materials. How to distinguish the quality of the harness? Understand the material of the wiring harness. The following is the material of wire harness selection.

The wiring harness is generally composed of wires, insulating sheaths, terminal blocks and packing materials.

1. Material selection of terminal

The copper used for terminal materials (copper parts) is mainly brass and bronze (brass is slightly lower in hardness than bronze), of which brass accounts for a larger proportion. In addition, different coatings can be selected according to different needs.

Second, the choice of insulating sheath

The commonly used materials of sheath material (plastic parts) are PA6, PA66, ABS, PBT, pp, etc. According to the actual situation, flame retardant or reinforcing materials can be added to the plastic to achieve the purpose of reinforcing or flame retardant, such as adding glass fiber reinforcement.

Third, the choice of wire harness

According to the different use environment, choose the corresponding wire material.

Fourth, the choice of dressing materials

Wire harness bandaging plays the role of wear resistance, flame retardant, anticorrosion, interference prevention, noise reduction, and beautification of appearance. Generally, the bandage material is selected according to the working environment and the size of the space. There are usually adhesive tapes, corrugated pipes, PVC pipes, etc. in the choice of packing materials.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!