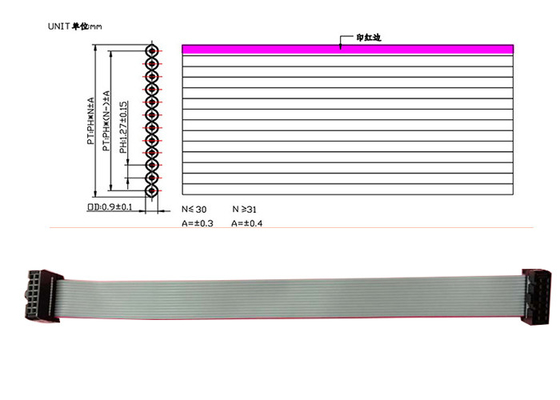

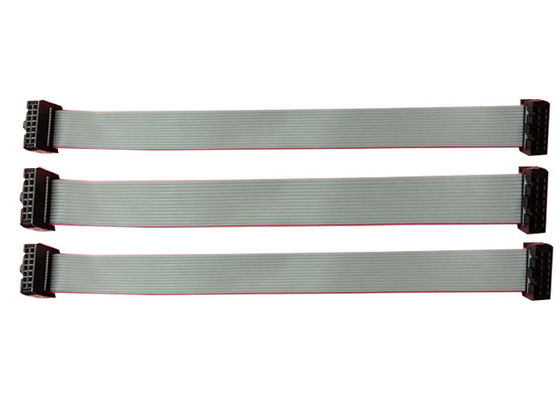

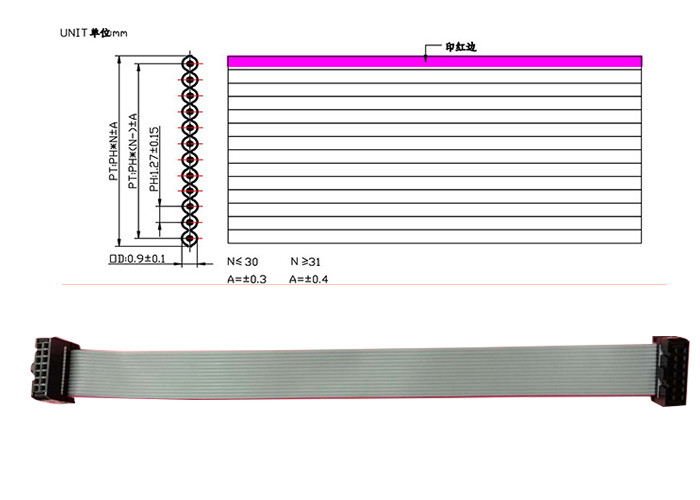

28AWG IDC Ribbon Cable Waterproof 45pins 1.27pitch PVC Female And Male Flexible Flat Cables

Product description:

The distinct multi-cable arrangement in a ribbon cable allows an insulation displacement connector (IDC) to be easily attached on its ends. Color coding is practiced and implemented in ribbon cables to avoid reverse connections, and, as a rule, the edge of the cable marked with a red stripe is connected to pin 1 on the connector. Also, different colored cables have been made available for easier identification of each conductor. They are often called hippie cables; conversely, they have remained specialized and comparatively pricey. The connectors at the ends of the cable are also specially notched so that they can only fit in a specific way, effectively preventing reverse connections.

Parameter:

| Product name |

Female And Male Flexible Flat Cables |

| Core number |

7/0.12 |

| Terminal |

Cooper (T=0.28) |

| Insulation material |

PVC |

| Sheath material |

PBT+30%Glass Fiber |

| Contact material |

Phosphor Bronze |

| Current Rating |

1.8Amp |

| Maximum withstand voltage |

AC 500V/1Minute |

| Insulation Resistance |

1000mΩ Min |

| Contact resistance |

15mΩ Max |

| Operation Temperature |

-40℃ to +105℃ |

| Interface type |

AC/DC |

| Features |

Fire resistance / flame retardant |

| Connectors |

1.27-45P |

| Work frequent |

Low frequency |

| Shape |

Strip |

| PIN |

45 pins |

| Pitch |

1.27mm |

| Wire gauge |

28AWG or customized |

| Wire length |

150mm or Customized |

| Wire Color |

Red edge gray row or Customized |

| Certificates |

RoHS,CE,UL,TUV,ISO |

| MOQ |

Small quantity can be accepted |

| Sample |

Samples confirmed first before mass production |

| Sevice |

OEM ODM accepted |

The IDC Ribbon cables is small in size and light in weight. The original design of the cable board was used to replace the larger wire harness wire. The IDC Ribbon cables is currently the only processing method to meet the requirements of miniaturization and mobile on the assembly board of the plug-in electronic sub-device. The IDC Ribbon cables is etched copper circuit or printed polymer thick film circuit on the polymer substrate. For devices that are thin, light, and have a compact and complex structure, their design and processing plans range from single-sided conductive circuits to complex multi-layer three-dimensional assembly. The total weight and volume of the gray cable is 70% less than the traditional round wire harness method.

Female and male connectors information :Plug-in connectors are divided into male and female ends, one side of the plug (protruding connector) is the male end, and the other side of the jack (recessed connector) is the female end, and the male and female terminals are injection molded. The two connectors have the difference between male and female, that is, the widely used connector, namely CONNECTOR. Generally, it refers to an electrical connector, that is, a device that connects two active devices. The male and female terminals are inserted into each other to achieve the working principle of transmitting current or signals. It is widely used in lighting, communications, medical, sensing, automotive, etc. Electronic device industry. The use of male and female end-to-end connectors has the following advantages:

1. Improve the production process:

The connector simplifies the assembly process of electronic products.

2. Easy maintenance:

If an electronic component fails, the failed component can be quickly replaced when the connector is installed;

3. Easy to upgrade:

With the advancement of technology, the components can be updated when the connector is installed, and the old ones can be replaced with new and more perfect ones;

4. Improve design flexibility:

The use of connectors gives engineers greater flexibility when designing and integrating new products, and when using components to form systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!