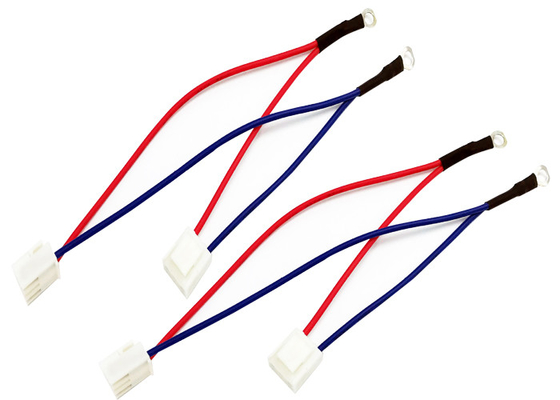

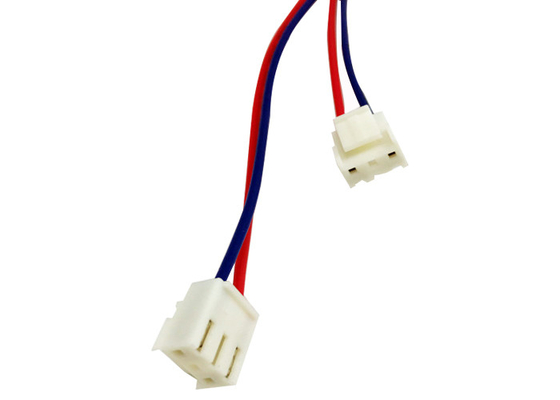

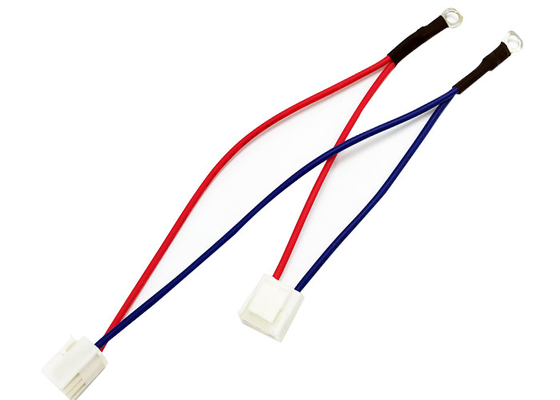

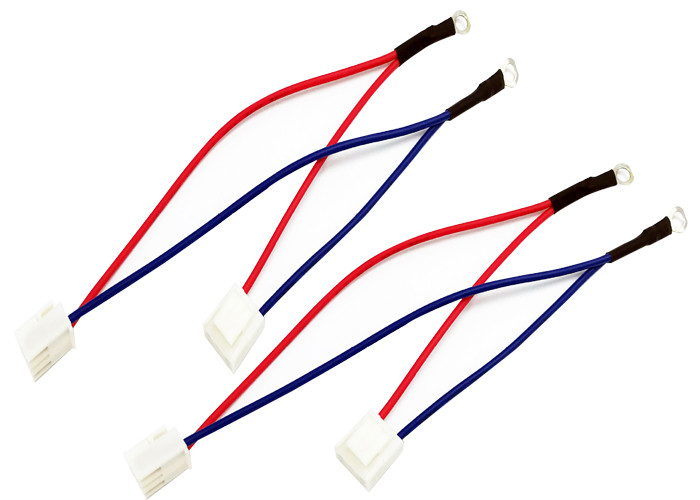

O-ring Custom Wiring Harness 4pins 300mm Female And Male Terminal Wire Harness

Parameter:

| Product name |

Female And Male Terminal Wire Harness |

| Terminal |

Cooper or customized |

| Interface type |

AC/DC or customized |

| Insulation material |

PVC or customized |

| Operation Temperature |

-40°C~+105°C |

| Features |

Fire resistance / flame retardant/waterproof |

| Connectors |

Customized |

| Work frequency |

Low frequency or customized |

| Shape |

Strip or customized |

| PIN |

4 pins or customized |

| Pitch |

2mm or customized |

| Wire gauge |

22AWG or customized |

| Wire length |

300mm or Customized |

| Wire Color |

Customized |

| Certificates |

RoHS,CE,UL,TUV,ISO |

| MOQ |

Small quantity can be accepted |

| Sample |

Samples confirmed first before mass production |

| Sevice |

OEM ODM accepted |

| Delivery Time |

3-15 days upon receipt of payment |

| Packaging |

00/200/300/500pcs per bag , then outside carton |

| Test |

Professional breakover and pulling force test before goods sent out |

| Lead time |

3-15 days |

Product information :

The standard of the wire harness is mainly calculated by calculating its crimping rate. The calculation of the crimping rate needs to pass a special instrument. The standard tester for the wire harness cross section developed by Suzhou Oka Optical Instrument Factory is the most suitable for testing whether the wire harness crimping is qualified. Effective detector. Mainly through the steps of cutting, grinding and polishing, corrosion, observation, measurement and calculation.

1. The detection and judgment of the wire harness burn-out failure:

In the circuit of the power supply system, the wire bundle is burnt wherever it is grounded. The junction of the burnt and intact part can be considered to be grounded; if the wire bundle is burnt to the wiring part of an electrical equipment , Indicating that the electrical equipment is malfunctioning.

2. Detection and judgment of short circuits, open circuits, and poor contact faults between lines:

The wire harness is squeezed and impacted by the outside, causing damage to the wire insulation in the wire harness, resulting in short circuits between the wires. When judging, you can disassemble the wiring harness connectors at both ends of the electrical equipment and the control switch, and use the electric meter or test lamp to detect the short circuit of the circuit.

a. Wire break fault, in addition to the obvious breaking phenomenon, common faults mostly occur between the wire and the wire terminal. After some wires are broken, the outer insulation layer and the wire terminals are intact, but the inner core wire of the wires and the wire terminals have been broken. When judging, you can do a tensile test on the conductive wire and the wire terminal suspected to be broken. During the tensile test, if the wire insulation becomes thinner, you can confirm that the wire has been broken.

b. The line is poorly connected, and the fault mostly occurs in the connector. When a fault occurs, it will cause electrical equipment to not work properly. When judging, connect the power supply of the electrical equipment, touch or pull the relevant connector of the electrical equipment, when touching a certain connector, the electrical equipment will work normally and suddenly, indicating that the connector malfunction.

Female and male connectors information :Plug-in connectors are divided into male and female ends, one side of the plug (protruding connector) is the male end, and the other side of the jack (recessed connector) is the female end, and the male and female terminals are injection molded. The two connectors have the difference between male and female, that is, the widely used connector, namely CONNECTOR. Generally, it refers to an electrical connector, that is, a device that connects two active devices. The male and female terminals are inserted into each other to achieve the working principle of transmitting current or signals. It is widely used in lighting, communications, medical, sensing, automotive, etc. Electronic device industry. The use of male and female end-to-end connectors has the following advantages:

1. Improve the production process:

The connector simplifies the assembly process of electronic products.

2. Easy maintenance:

If an electronic component fails, the failed component can be quickly replaced when the connector is installed;

3. Easy to upgrade:

With the advancement of technology, the components can be updated when the connector is installed, and the old ones can be replaced with new and more perfect ones;

4. Improve design flexibility:

The use of connectors gives engineers greater flexibility when designing and integrating new products, and when using components to form systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!