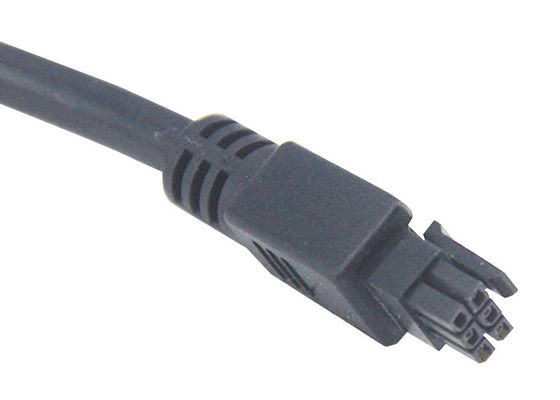

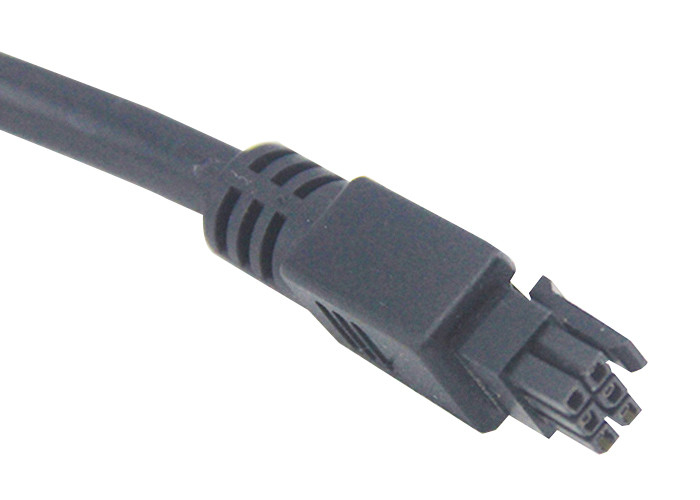

6pins Overmolded Cable Assemblies 1500mm Black VC To OBD Overmolded Terminal Wires

Production information :

Cable Assembly Overmoldering Process

The overmolding of a cable assembly is accomplished by forcing a material into a mold cavity under a great deal of pressure. For cable assemblies, the most popular materials used for an overmold are thermoplastic or thermoset materials. The injection molding machine, also known as a press, consists of a storage area for the mold resin. Sometimes it can be called a hopper. Delivery for the material is usually an injection ram or a screw-type plunger enclosed inside a metal tube also known as a barrel. Heating elements are installed into the barrel of the machine causing the mold resin to be heated to a molten state.

The process begins with the resin specified for the mold is fed into the heated barrel of the molding machine at the hopper end. It is then mixed with any desired colorants and transits the length of the barrel to the actual mold where the resin and colorant mixture are forced in the mold cavities. Once inside the mold cavity, the material will cool taking on any features designed into the mold itself including logos, trade names, or part numbers.

Parameter:

| Product name |

Overmolded Terminal Wires |

| Work frequency |

Low frequency |

| Features |

Moisture-proof |

| Contact material |

Cooper |

| Pins |

6pins or customized |

| Maximum outer diameter |

Customized |

| Interface type |

Customized |

| Insulation material |

PVC or customized |

| Connectors |

Customized |

| Shape |

Strip or customized |

| Wire length |

1500mm or Customized |

| Wire Color |

Black or Customized |

| Certificates |

RoHS,CE,UL,TUV,ISO |

| MOQ |

Small quantity can be accepted |

| Sample |

Samples confirmed first before mass production |

| Sevice |

OEM ODM accepted |

| Delivery Time |

3-15 days upon receipt of payment |

| Packaging |

100/200/300/500pcs per bag , then outside carton |

| Test |

Professional breakover and pulling force test before goods sent out |

| Lead time |

3-15 days |

Conductor Sizes

We can extrude conductors as small as 34 gauge and as large as 12 gauge. These can be combined to create a mixed gauge cable.

Conductor Colors

Our custom wire and cable harness capabilities are extensive, from 1 conductor to cables with more than 50 conductors. Custom colors, striping and marking are available to meet your wiring harness design requirements.

Stranding Sizes

Your conductors can be made with stranding as small as 0.002 inches (0.05mm) which is excellent for hi-flex, supple cables. If you just need a standard power conductor we can use stranding as large as 0.01 inches (0.25 mm). Stranding can be bare copper, tinned stranding, tinned conductor or even plated with precious metals such as silver for increased conductivity.

Conductor Insulation

The first protection in any cable is the conductor’s insulation. Our wire and cable extrusion capabilities include a wide range of materials to match your requirements for flexibility, abrasion resistance and environmental conditions. We use the range from basic PVC, PE or PP. We also use insulating materials such as natural rubber, PU, TPE, PTFE (Teflon®) and silicone.

Materials

Polyvinylchloride (PVC)

Polyurethane (PU)

Thermoplastic elastomer (TPE)

Thermoplastic polyester elastomer (TPEE)

Thermoplastic vulcanizate (TPV)

Polytetrafluoroethylene (Teflon®)

Silicone

The hardness or softness of each material can be varied.

Ul® Certified Wire & Cable

There are many standard UL® cable types. UL® standards help designers choose a cable with known specifications instead of creating one from scratch. We are certified by UL® to produce many standard types of wire and cable harnesses.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!