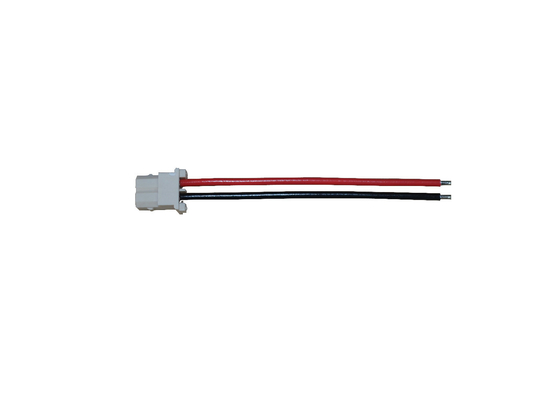

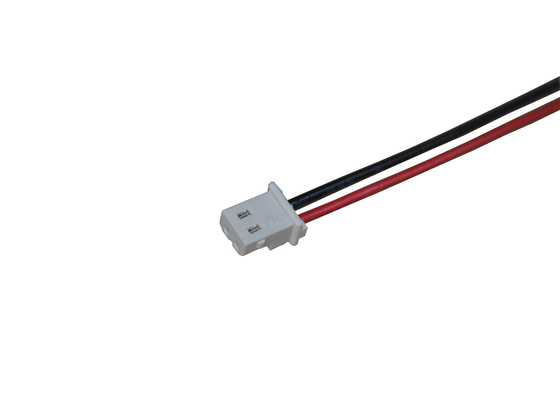

ZH1.5mm Electronic Wire 26awg Wire Gauge Female Terminal 50mm Long Tail Tinned Cable Wire Harness

About electronic wire harness:

Electronic wires are generally used for weak current projects, such as internal wiring of electronics and electrical equipment. It has the advantages of lightness, thinness, shortness, small size, variety, specifications, insulation and good safety performance. Electronic wires are mainly used in the electronics industry. The electronic wires can be classified into PVC, SRPVC, XLPE electronic wires, UL certified electronic wires, and low-smoke halogen-free electronic wires.

Parameters:

| Place of Origin |

Jiangsu,China |

| Brand Name |

SYH |

| Model Number |

SYH-E008 |

| Application |

Widely used in various electronic products. Such as: LED, lighting, security monitoring, 3D printing, automation equipment, data, lamps, instruments, power, industrial control, petrochemical, transportation, network communication and other fields. |

| Connectors |

1.5mm connector |

| Wire |

28 awg |

| Wire length |

50mm or Customized |

| Wire Color |

black and red or Customized |

| Certification |

ISO9001, T/S16949, Rohs |

| MOQ |

Small quantity can be accepted |

| Sample |

Sample can be provided for evaluating |

| Sevice |

OED ODM accepted |

| Delivery Time |

3-15 days upon receipt of payment |

| Packaging |

Outside carton |

| Test |

Professional breakover and pulling force test before goods sent out |

AWG(AMERICAN WIRE GANGE) specification:

| AWG |

Outer diameter (mm) |

Cross-sectional area(mm²) |

Resistance (MΩ) |

AWG |

Outer diameter (mm) |

Cross-sectional area(mm²) |

Resistance (MΩ) |

| 4/0 |

11.684 |

107.2193 |

0.16 |

27 |

0.3607 |

0.1022 |

198.74 |

| 3/0 |

10.4038 |

85.0114 |

0.2 |

28 |

0.3200 |

0.0804 |

214.32 |

| 2/0 |

9.2659 |

67.4321 |

0.26 |

29 |

0.2870 |

0.0647 |

266.47 |

| 1/0 |

8.2525 |

53.4880 |

0.32 |

30 |

0.2540 |

0.0507 |

640.26 |

| 1 |

7.3482 |

42.4086 |

0.41 |

31 |

0.2261 |

0.0401 |

429.56 |

| 2 |

6.5430 |

33.6240 |

0.51 |

32 |

0.2302 |

0.0324 |

531.65 |

| 3 |

5.8268 |

26.6652 |

0.65 |

33 |

0.1803 |

0.0255 |

674.98 |

| 4 |

5.1892 |

21.1492 |

0.82 |

34 |

0.1600 |

0.0201 |

857.28 |

| 5 |

4.6203 |

16.7657 |

1.03 |

35 |

0.1422 |

0.0159 |

1085.00 |

| 6 |

4.1148 |

13.2980 |

1.63 |

36 |

0.1270 |

0.0127 |

1361.02 |

| 7 |

3.6652 |

10.5509 |

2.06 |

37 |

0.1143 |

0.0103 |

1680.27 |

| 8 |

3.2639 |

8.3669 |

2.6 |

38 |

0.1016 |

0.0081 |

2126.60 |

| 9 |

2.9058 |

6.6315 |

3.28 |

39 |

0.0889 |

0.0062 |

2777.60 |

| 10 |

2.5883 |

5.2615 |

4.14 |

40 |

0.0787 |

0.0049 |

3540.64 |

| 11 |

2.3038 |

4.1684 |

5.21 |

41 |

0.0711 |

0.0040 |

4339.99 |

| 12 |

2.0523 |

3.3081 |

6.56 |

42 |

0.0635 |

0.0032 |

5444.09 |

| 13 |

1.8288 |

2.6268 |

8.28 |

43 |

0.0559 |

0.0025 |

7030.07 |

| 14 |

1.6281 |

2.0820 |

10.44 |

44 |

0.0508 |

0.0020 |

8506.39 |

| 15 |

1.4503 |

1.6521 |

10.44 |

45 |

0.0447 |

0.0016 |

10984.5 |

| 16 |

1.2903 |

1.3076 |

13.18 |

46 |

0.0399 |

0.0012 |

138.04 |

| 17 |

1.1506 |

1.0398 |

16.58 |

47 |

0.0356 |

0.0010 |

17360.0 |

| 18 |

1.0236 |

0.8229 |

20.95 |

48 |

0.0315 |

0.0008 |

22129.0 |

| 19 |

0.9119 |

0.6530 |

26.40 |

49 |

0.0282 |

0.0006 |

27615.9 |

| 20 |

0.8128 |

0.5189 |

33.23 |

50 |

0.0251 |

0.0005 |

34716.4 |

| 21 |

0.7239 |

0.4116 |

41.89 |

51 |

0.0224 |

0.0004 |

43938.0 |

| 22 |

0.6426 |

0.3243 |

53.16 |

52 |

0.0198 |

0.0003 |

55926.3 |

| 23 |

0.5740 |

0.2588 |

66.62 |

53 |

0.0178 |

0.0002 |

69439.9 |

| 24 |

0.5105 |

0.2047 |

84.22 |

54 |

0.0157 |

0.0002 |

88516.0 |

| 25 |

0.4547 |

0.1624 |

106.19 |

55 |

0.0140 |

0.0002 |

112481.2 |

| 26 |

0.4039 |

0.1281 |

134.59 |

56 |

0.0124 |

0.0001 |

111714.1

|

The composition of the wiring harness:

The components of the ordinary wiring harness are: wires, terminals, plastic parts.

The composition of complex wiring harnesses is to be added: tape, cable ties, sleeves, jackets, labels, etc.

Sheath (HSG)

Sheath (plastic shell), usually made of plastic, inserts the wire of the crimped terminal into it to ensure the reliability of the connection. The main materials are PA6, PA66, ABS, PBT, PP, etc. The jacket (HSG) is divided into There are two types of F (female) plastic shells and M (male) plastic shells. Most of these shells have a locking mechanism common to F / M.

Terminal

A shaped hardware component, crimped on the wire to connect different wires to transmit signals, divided into male terminal, female terminal, ring terminal and round terminal The material is mainly brass and bronze (brass is slightly lower in hardness than bronze), of which brass accounts for a larger proportion.

Wire (low-voltage wire, 60-600V)

① Conventional wire type: (usually American standard line UL)

National standard line: QVR, QFR, QVVR, QBV, QBVV, etc.

Japanese standard line: AV, AVS, AVSS, AEX, AVX, CAVUS, CIVUS, etc.

German mark: FLRY-A, FLRY-B, etc.

American standard line: SXL, TXL, etc.

Common specifications include wires with a nominal cross-sectional area of 0.35, 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 4.0, 6.0, etc.

② Composition of electric wire

From inside to outside

1. Conductor (copper wire)

2. Insulator (PVC, SR-PVC, PP, PE.FOAM-SKIN)

3. Isolation layer (aluminum foil, winding, braiding)

4. Coating (PVC, PU), etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!