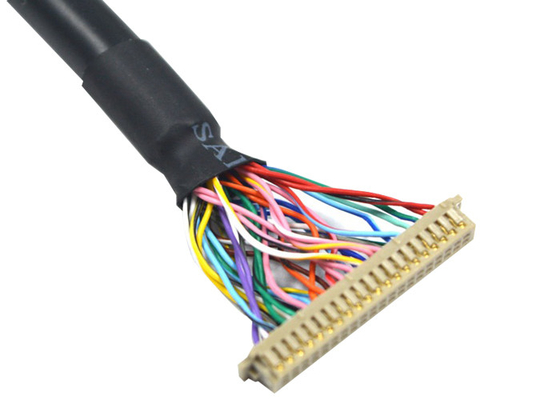

1.25 pitch LVDS Cable Black 260mm UL20276 28AWG LVDS Display Connection Cable

Product overview :

LVDS cables are the best choice where low power exists and a large amount of data transfer is required. The main application of LVDS system and cables is in computers. Before LVDS cable assemblies were introduced, the data transfer rate was too slow and cables used to occupy more space.

LVDS is now supported by SCSI standards. This allows cable assemblies built for LVDS to support higher data rates and longer cable lengths.

LVDS cable assemblies are also used in video interfacing devices. They are more commonly used for transporting video data from graphics adapters to computer monitors particularly LCD screens, FPD-Link or OpenLDI standards. These standards of LVDS cable assemblies allow a maximum pixel clock of 112 MHz, which suffices for a display resolution of 1400 x 1050 (SXGA+) at 60 Hz refresh. A dual link can boost the maximum display resolution to 2048 x 1536 (QXGA) at 60 Hz. FPD-Link works with cable lengths up to about 5 m, and LDI extends this to about 10 m.

Parameter:

| Product name |

LVDS Display Connection Cable |

| Shape |

Strip |

| Work frequency |

Low frequency |

| Interface type |

AC/DC |

| Feature |

Fire retardant/flame retardant |

| Pins |

18PIN |

| Pitch |

1.25mm or customized |

| Insulation material |

PVC |

| Contact materia |

Copper |

| Wire gauge |

UL20276 28AWG or customized |

| Wire length |

260mm or Customized |

| Wire Color |

Black or Customized |

| Certificates |

RoHS,CE,UL,TUV,ISO |

| MOQ |

Small quantity can be accepted |

| Sample |

Samples confirmed first before mass production |

| Sevice |

OEM ODM accepted |

| Delivery Time |

3-15 days upon receipt of payment |

| Packaging |

00/200/300/500pcs per bag , then outside carton |

| Test |

Professional breakover and pulling force test before goods sent out |

| Lead time |

3-15 days |

The benefits of LVDS include:

- Compatible to Low-voltage power supply

- Low noise generation

- High noise rejection

- Robust transmission signals

- Ability to be integrated into system level ICs

Shipping:

1. FedEx/DHL/TNT/UPS/EMS/Aramex/SF for samples, Door-to-Door;

2. By Air or by Sea for batch goods;Airportport receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3-7 days for samples; 10-30 days for batch goods.

FAQ:

Q: When will you start to help design?

A: We sketch simple solution for initial discussion, after quotation and order placed then start to drawing and double confirm with client for the design.

Q: How can i get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q:Can I buy samples placing orders?

A:Yes.Please feel free to contact us.

Q: Are all aftermarket wiring harnesses the same?

A:Definitely not. Unfortunately, shoddy manufacturers abound and buying a harness from a non-reputable wiring harness supplier can put your project’s assets at serious risk of failure. At SYH, we follow strict quality assurance/quality control procedures, use and maintain UL® standards for wiring, and are proud to have received and maintain ISO 9001:2015 certification for quality. We do all of this to ensure we remain wire harness and cable assembly manufacturers of distinction, engineering the precise solutions our clients demand, and making sure these systems are robust enough to stand up to years of use.

Q: What is the UL® standard for wire harness manufacturers?

A: United Laboratories (UL) is one of only a select few corporations that have been approved by the U.S. Occupational Safety and Health Administration (OSHA) for testing and certifying both safety and uniform functionality of wiring and cable components. By only using UL-certified components, we can ensure our products operate the same way, within known specification ranges, year in and year out. Rather than having to design a cable from scratch each time, this allows design staff to focus on other project variables such as weight strain reduction within the harness, type and size of conductors, insulation material, etc. If you don’t see that your wire harness and cable assembly manufacturers are using UL-certified wires and cables, don’t trust your integral electrical systems to a system which could fail when you need it the most.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!